| TECHNICAL SPECIFICATIONS |

| ELECTRICAL SPECIFICATIONS |

| Emission |

High-level amplitude modulation (A3); frequency shift keying (F1) |

| Frequency Range |

3.95 to 26.5 Mc/s, continuous coverage |

| Frequency Control |

By oven controlled crystal oscillator (two furnished) or by either of two customer furnished external signal sources |

| Frequency stability with Type CR-27/U Crystals |

From +5 to +50°C and primary voltage variation ±10%, less than 5 parts per million frequency change per 24-hour period. Greater stabilities obtainable with higher stability crystals. |

| Tuning Time |

Frequency change accomplished in 20 seconds or less |

| Tuning Mode |

Automatic - with operator override capability |

| Power Output |

At least 250-kw unmodulated carrier power, 100% sine wave or trapezoidal modulation |

| Carrier Shift |

Less than 5%, exclusive of that caused by primary power regulations |

| Output Impedance |

300 ohms, balanced (75 ohms unbalanced output available) |

| Allowable VSWR |

1.5:1 maximum |

| Type of Modulation |

High level AM, FSK |

| Modulation Capability |

Capable of 100% sine wave or sine wave clipped 9 db. Less than 5% tilt or overshoot for clipped waveform at 100% modulation |

| Modulation Duty Factor |

Continuous at 100% sine wave; 5 minutes at 9 db clipped sine wave |

| Audio Input for 100% Modulation |

+10 dbm ±2 db |

| Audio Input Impedance |

600/150 ohm, balanced or unbalanced |

| Audio Response |

Within 1 db from that at 1000 cps between 100 and 7500 cps and within 2 db between 50 to 10,000 cps, at all modulation levels up to 95% |

| Audio Distortion |

Not more than 4% distortion when modulated 95% over the frequency range of 100 to 5000 cps; and not more than 5% from 50 to 100 cps and from 5000 to 7500 cps |

| Noise Level |

Carrier hum and extraneous noise is at least 50 db (unweighted) below 100% modulation |

| Harmonic and Spurious |

All harmonics and harmonically related spurious emissions are at least 80 db below carrier level. Incidental phase modulation products that occur close to the carrier in the output of the transmitter are at least 43 db below 1 radian |

| Power Input |

At rated carrier output; 475 kw at .95 power factor. At 100% sine wave; 710 kw at .95 power factor |

| Power Source |

4160 volts ±3%; 50 ±3 cps; 3 phase, 3-wire, standard (60 ±3 cps and other voltages optional) |

| ENVIRONMENTAL SPECIFICATIONS |

| Altitude |

0 to 6000 feet |

| Temperature |

Operating: Standard Inside Ambient: +5° to +50°C at sea level, +5° to +38°C at 6000 feet altitude

Storage: -35° to +60°C |

| Humidity |

0 to 95% relative humidity |

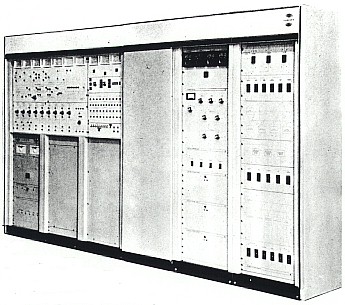

| MECHANICAL SPECIFICATIONS |

| Size |

Not over 800 square feet, over-all; 13 feet minimum floor-to-ceiling height |

| High Voltage Power Supply |

400 square feet |

| High Voltage Enclosure |

250 square feet |

| Operational Area |

150 square feet |

| Transmitter Weight |

48,925 pounds |

The new 821A-1 250 kw transmitter is Collins Radio Company's latest addition to the high-power HF broadcast product line. With totally new and unique design features, this high frequency transmitter advances present day techniques of super-power transmitter design.

The new 821A-1 250 kw transmitter is Collins Radio Company's latest addition to the high-power HF broadcast product line. With totally new and unique design features, this high frequency transmitter advances present day techniques of super-power transmitter design.