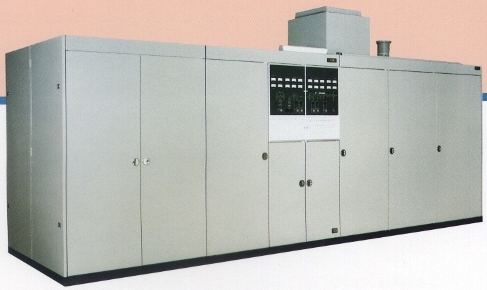

| GENERAL DESCRIPTION |

* Centralized Display System

* Centralized Display System| TECHNICAL SPECIFICATIONS | |

| Carrier power output | 300 kW +5,-10% |

| Type of emission | A3E (DSB) |

| Frequency range | 5.9 to 21.9 MHz Covering the international broadcast band in 100 Hz steps |

| Number of preset frequencies | 100 frequencies, maximum |

| Frequency Stability | 2 x 10-8/day |

| Frequency change time | 30 sec. average |

| Output impedance | 50 ohms unbalanced |

| Suitable coaxial Copper tube feeder | WX-203D (8 in) or its equivalent |

| Permissible standing wave ratio | Less than 2.0 VSWR |

| Spurious radiation | Below 45 MHz: Less than 25 mW Above 45 MHz: Less than 10 mW |

| Audio signal input | 150 to 3500 Hz, 0 dBm into 600 ohms |

| Modulation linearity | Linear up to 95% modulation with 100 Hz |

| Audio frequency distortion | Less than 3% up to 80% modulation. Less than 5% up to 95% modulation. |

| Signal-to-noise ratio | Better than 55 dB at rated output with 1000 Hz 80% modulation |

| Mains supply | (1) 200 V AC 3-phase, 100 kVA (2) 6600 V AC 3-phase, 670 kVA ave. Total power factor, better than 90% Please state mains data in enquiries |

| Weight | 7500 kg (transmitter body only) |

| Specifications may change without notice | |

| TUBE COMPLEMENT | |||

| RF stages | AF stages and modulator | ||

| Number | Type | Number | Type |

| 1 | 4CM500,000G or TH558 | 2 | TH573 |

| THIS TYPE OF TRANSMITTER IS INSTALLED IN THE FOLLOWING COUNTRIES | |||||

| ITU | Country | ITU | Country | ||

| J | JAPAN | CLN | SRI LANKA | ||