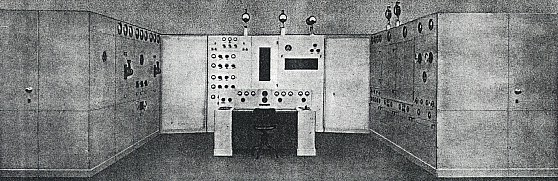

| GENERAL DESCRIPTION |

INTRODUCTION

INTRODUCTION| TUBE COMPLEMENT | |||||

| RF stages | AF stages and modulator | Rectifiers | |||

| Number | Type | Number | Type | Number | Type |

| 2 | TA 12/20000 K | 2 | MA 12/15 | 1 | 506 |

| 2 | TA 10/5000 K | 2 | MA 4/500 | 3 | DCG 5/2500 |

| 4 | QB 2/75 | 1 | MC 1/60 | 5 | DCG 4/400 |

| 1 | QC 05/15 | 4 | DCG 10/15 | ||

| THIS TYPE OF TRANSMITTER IS INSTALLED IN THE FOLLOWING COUNTRIES | |||||

| ITU | Country | ITU | Country | ||

| IND | INDIA | INS | INDONESIA | ||

| BRM | MYANMAR | ||||