| GENERAL DESCRIPTION |

GENERAL

GENERAL CONSTRUCTION

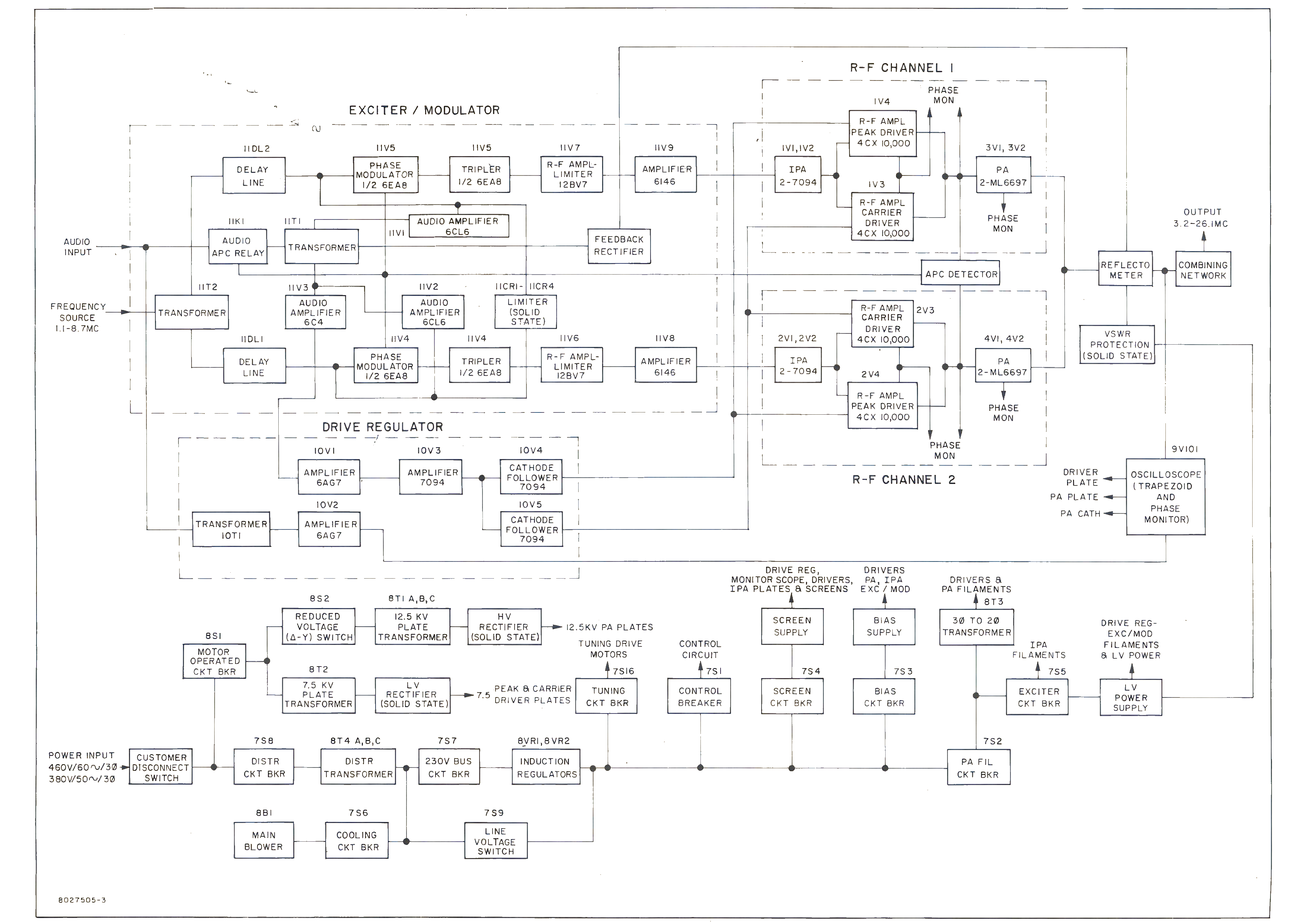

CONSTRUCTION The IPA's are Class C amplifier. employing a parallel pair of 7094 tetrodes to provide approximately 100 watts to the following driver stage. Input and output circuits of the IPA's are frequency compensated by bandswitched inductive elements.

Proper drive for the final power amplifier stage of each channel is provided by a driver stage consisting of two 4CX10,000 tubes. Because of the widely varying drive requirements and load impedances, the two driver tubes are biased at different levels. Thus, at the carrier power level and below, one tube (carrier driver) is supplying power; above the carrier power level, both tubes (carrier and peak driver) are supplying power to drive the final stage. A 180° network (two 90° pi networks in cascade) is used to match the relatively high impedance of the driver stage to the low input impedance of the grounded-grid power amplifiers which follow. This network provides the correct transformation ratios under varying load impedances without incidental phase modulation.

The IPA's are Class C amplifier. employing a parallel pair of 7094 tetrodes to provide approximately 100 watts to the following driver stage. Input and output circuits of the IPA's are frequency compensated by bandswitched inductive elements.

Proper drive for the final power amplifier stage of each channel is provided by a driver stage consisting of two 4CX10,000 tubes. Because of the widely varying drive requirements and load impedances, the two driver tubes are biased at different levels. Thus, at the carrier power level and below, one tube (carrier driver) is supplying power; above the carrier power level, both tubes (carrier and peak driver) are supplying power to drive the final stage. A 180° network (two 90° pi networks in cascade) is used to match the relatively high impedance of the driver stage to the low input impedance of the grounded-grid power amplifiers which follow. This network provides the correct transformation ratios under varying load impedances without incidental phase modulation.

| TUBE COMPLEMENT | |||||

| RF stages | AF stages and modulator | Rectifiers | |||

| Number | Type | Number | Type | Number | Type |

| 4 | ML-6697 | ||||

| 4 | 4CX10,000 | ||||

| 4 | 7094 | ||||

| THIS TYPE OF TRANSMITTER IS INSTALLED IN THE FOLLOWING COUNTRIES | |||||

| ITU | Country | ITU | Country | ||

| EQA | ECUADOR | PAK | PAKISTAN | ||

| PLW | PALAU | USA | USA | ||

| CVA | VATICAN CITY | ||||